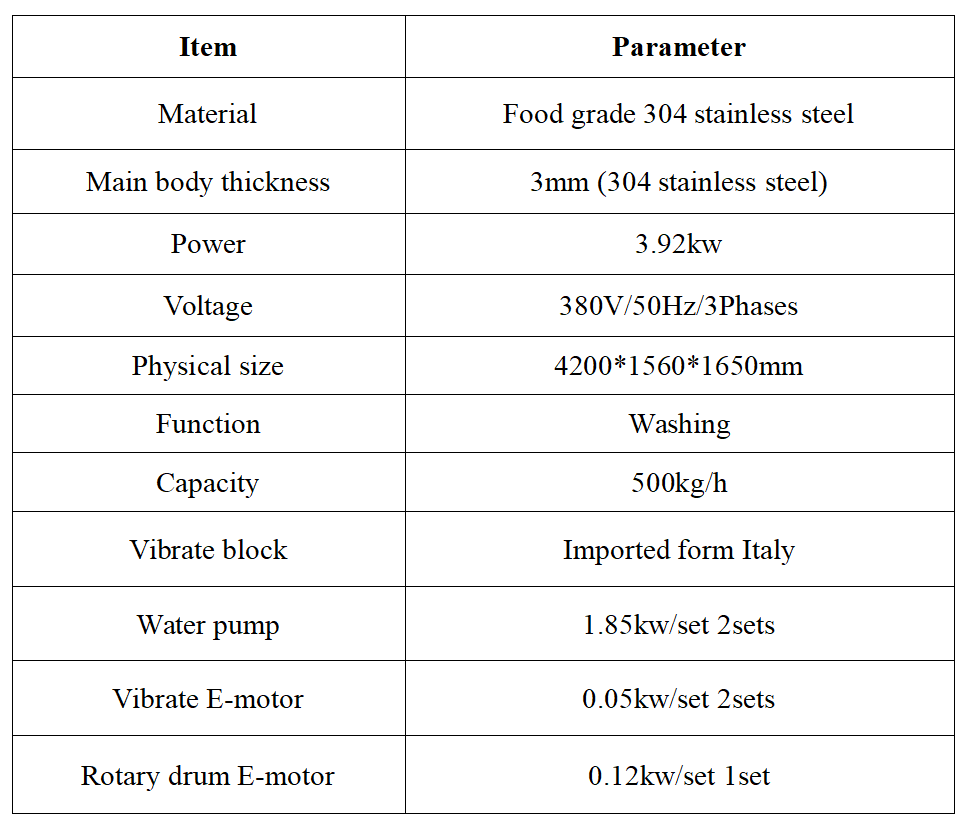

Vortex washing machine

Horizontal vortex spiral washing plus vibrate remove water, suitable for washing leafy vegetable, root vegetable after cutting and pickled vegetable. Such as Chinese cabbage, lettuce, spinach and pickled radish, cabbage and so on. Vortex and air bubble double washing, used to eliminate the huddle phenomenon which happened by using the traditional vortex washing machines to wash the uncut vegetables. High pressure air bubble can separate the huddled vegetables which settles the disadvantage of the traditional vortex washing machine can only wash the cut vegetables. The exhaust pipe is equipped with a relief valve to adjust the bubble strength when cleaning different materials.

Features:

1. This machine is used the natural mechanics principle of water flowing and scouring to ensure that the vegetables will not be damaged during the entire washing process, thus achieving the goal of industrialized standardized process of net vegetable processing.

2. It is used for the cleaning of materials to remove impurities and drains, and completely removes light or small heavy debris such as sediment, dust, pebbles, etc., and effectively kills and removes pesticide residues in the food material.

3. The tank inlet and the two sides are equipped with a flushing pipe, which is supplied by a high-pressure pump. After the action of the flushing water, the water in the tank produces a swirling state. The material is rotated forward by the action of the water flow to complete cleaning. . The material conveying vibration is drained and the water flows through the orifice of the vibrating screen and flows into the bottom water tank to complete the circulation of the entire waterway.

1. This machine is used the natural mechanics principle of water flowing and scouring to ensure that the vegetables will not be damaged during the entire washing process, thus achieving the goal of industrialized standardized process of net vegetable processing.

2. It is used for the cleaning of materials to remove impurities and drains, and completely removes light or small heavy debris such as sediment, dust, pebbles, etc., and effectively kills and removes pesticide residues in the food material.

3. The tank inlet and the two sides are equipped with a flushing pipe, which is supplied by a high-pressure pump. After the action of the flushing water, the water in the tank produces a swirling state. The material is rotated forward by the action of the water flow to complete cleaning. . The material conveying vibration is drained and the water flows through the orifice of the vibrating screen and flows into the bottom water tank to complete the circulation of the entire waterway.