Welcome to LIANTUO

Why Choose LIANTUO?

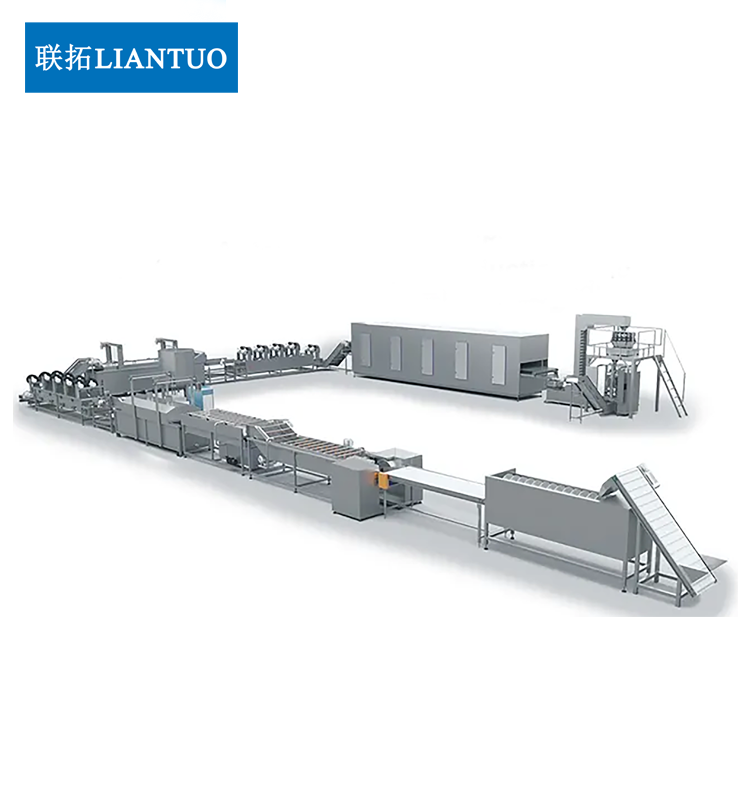

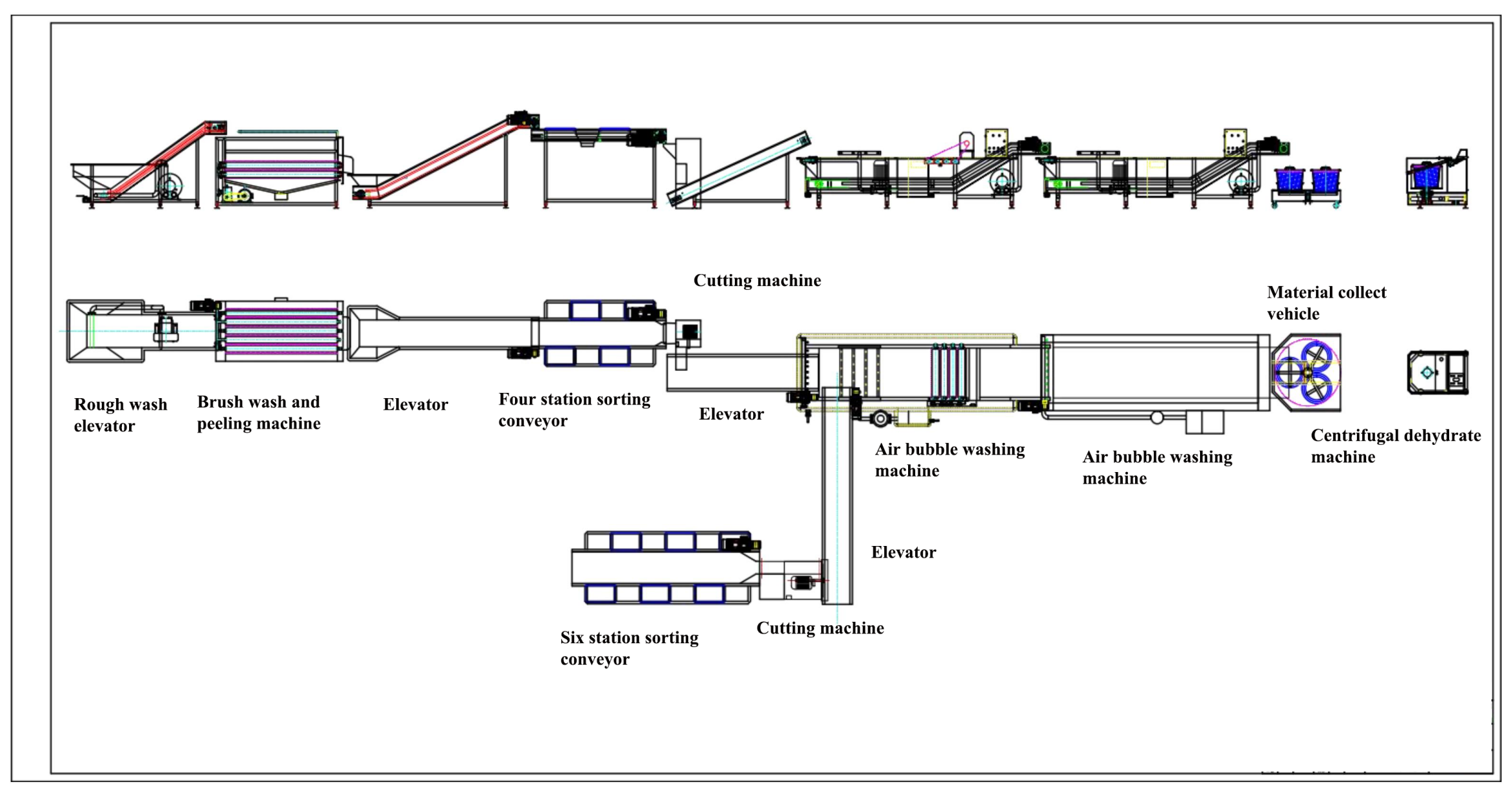

We are specializing in research and development and manufacturing clean vegetable processing line, fruit and vegetable crisp chips vacuum puff processing line, french fries and chips processing line, meatball processing line, fruit and vegetable washing machine, crate washing machine, air drying. machine, hot air drying machine, centrifugal dehydrate machine, vibrator, vegetable cutting machine, frying machine, blanching machine, pasteurization machine, retort, vacuum freeze drying machine, vacuum puffing machine, shrimp shell peeling machine, various meat processing equipment and packing machine, now has all kinds of mechanical processing equipment, which can meet the needs of users at different levels.

Service & Support

Superior machinery supplier, turnkey project solution.

Communication

Communicate the detailed requests

Delivery

Delivery the machine to customer

Design

Design the machine

Installation

Install the machine

Production

Produce the machine accordingly

After-sales service

Lifetime after-sales service

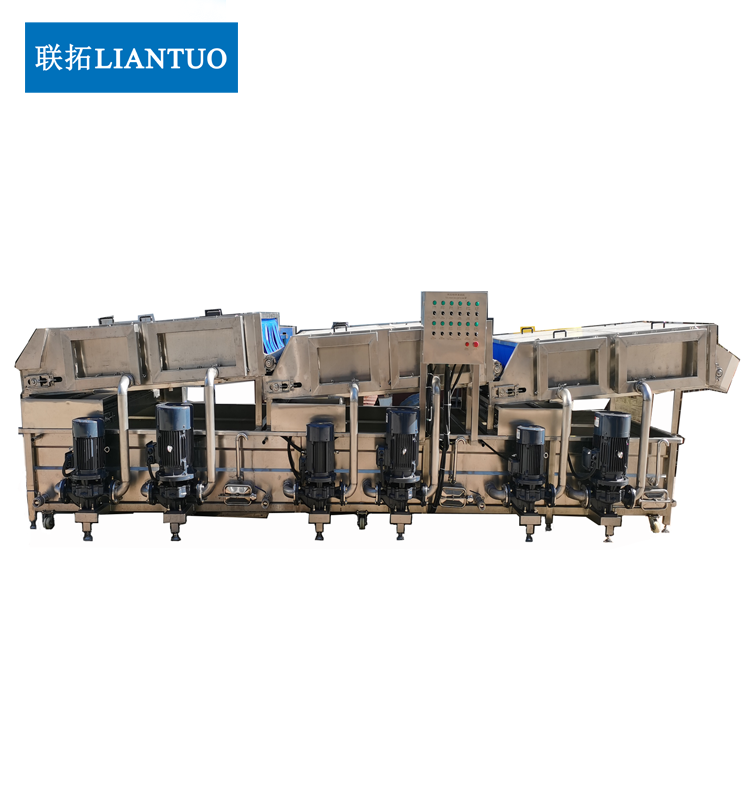

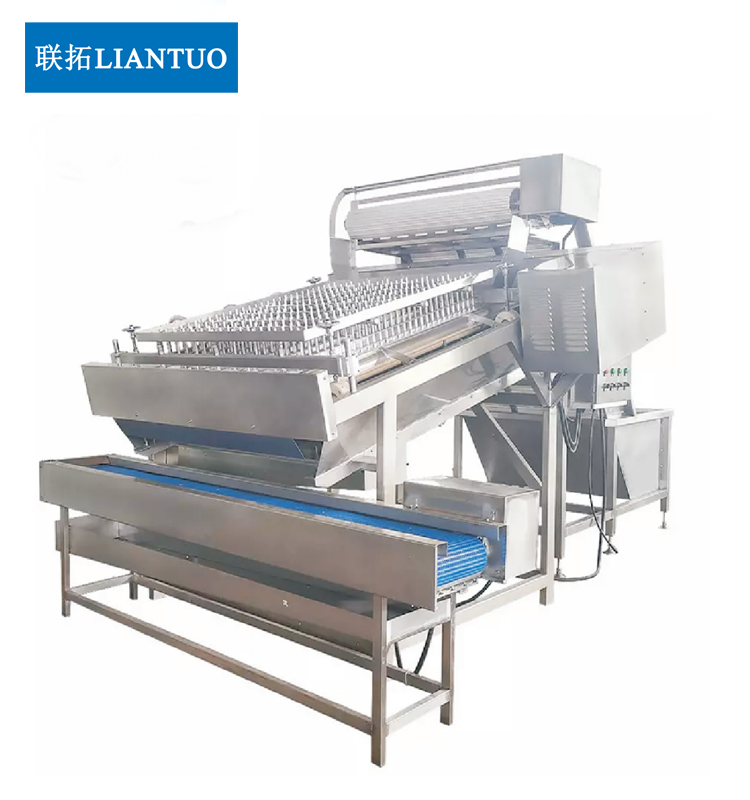

Fruit and vegetable process machine

clean vegetable processing line, fruit and vegetable crisp chips vacuum puff processing line, french fries and chips processing line, meatball processing line, fruit and vegetable washing machine, crate washing machine, air drying. machine, hot air drying machine, centrifugal dehydrate machine, vibrator, vegetable cutting machine, frying machine, blanching machine, pasteurization machine, retort, vacuum freeze drying machine, vacuum puffing machine etc.

Meat process machine

jacketed kettle, meat grinder, meat cube cutting machine, stuffing machine, saline injection machine, vacuum tumbler, chopping machine, smoking oven, meatball machine, sausage filling machine, meat planer etc.

Shrimp shell peeling machine

The main body is made of high-quality 304 stainless steel, and all parts and materials meet the hygienic production requirements. Compared with traditional processing methods, it saves a lot of labor, eliminates secondary pollution, greatly improves production efficiency, and is suitable for large-scale processing of shrimp. The equipment has a high degree of automation, open structure design, easy cleaning, and simple operation and maintenance. For customers with large output, multiple peeling machines can be used in parallel, and different numbers of peeling machines can be opened according to the production needs, making the production plan more flexible.